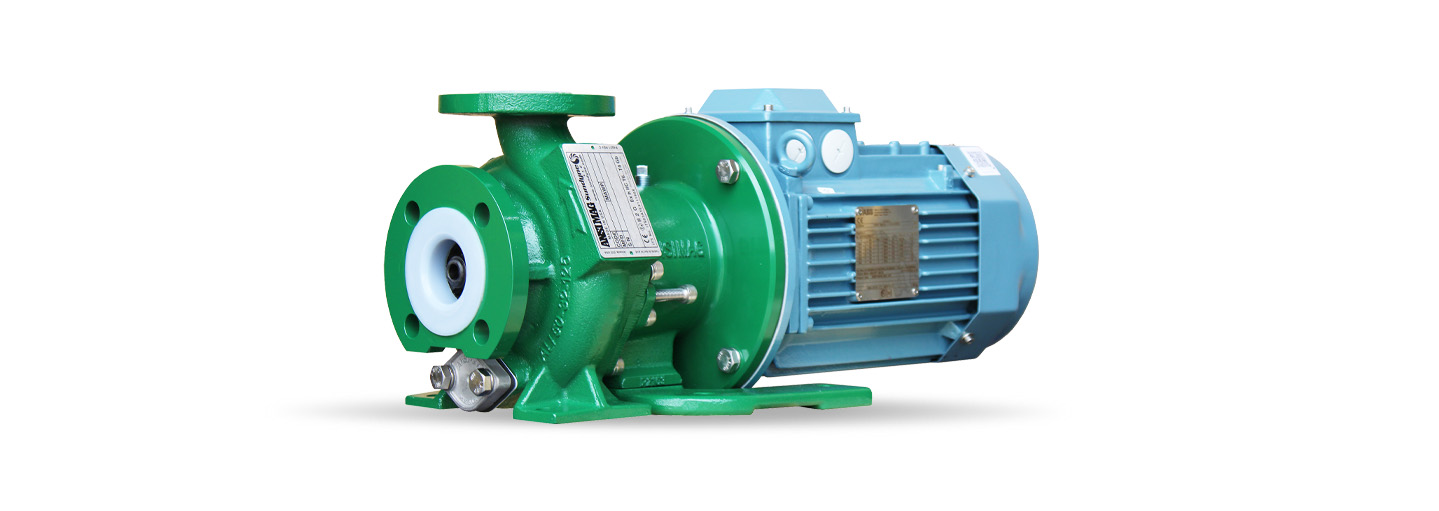

Ansimag: Centrifugal pumps, sealles, non-metallic, magnetic drive

Since 1994, Drotec distributes Ansimag (Sundyne Group) magnetically coupled centrifugal pumps in Argentinano seals or gaskets, completely hermetic free of leaks and emissions.

Its innovative design allows pumping with great safety and under very heavy service conditions all kinds of corrosive liquids, among others, sulfuric, hydrochloric, hydrogen sulfide, nitric, phosphoric, chromic and sodium hydroxide acids, sodium hypochlorite, solvents, ferric chloride, hydrogen peroxide etc

The standard materials in contact with the liquid to be pumped are ETFE (Tefzel), FKM (Viton) and Silicon Carbide for bushings and shafts. This set of materials allows handling the vast majority of corrosive liquids. As an alternative, PFA is offered instead of ETFE and Teflon Gore-Tex instead of Viton.

Other notable aspects of the Ansimag pumps are:

- Fixed (non-rotating) shaft with exclusive design allows handling up to 20% solids by weight

- Iron-boron-neodymium magnets that transmit up to 100 HP with reduced dimensions

- Impeller assembly composed of two parts: encapsulated driven magnet and impeller (hydraulic part). This allows optimization of injection manufacturing processes, as well as maintenance.

- Manufactured according to ANSI standards

- Working temperatures up to 121°C

- Wide range of models available,horizontal from 2 to 100 HP, vertical in-line and self-priming pumps.

- Directly coupled to the motor, they are very easy to disassemble, check and carry out maintenance operations on the installation site without special tools and without disconnecting the pump body from the piping.

- Suspended solids: up to 20% by weight and size of 6.4 mm. For higher concentrations consult.

- In the K+ and KF series, the impeller assembly is made up of two parts: encapsulated driven magnet and impeller (hydraulic part). This allows optimization of injection manufacturing processes, as well as maintenance. Provides longer useful life from the point of view of chemical attack.

Our services include, in addition to after-sales service, more than 30 years of experience in applications of liquids used in the industry that are at your service since we receive your query, advising and providing support in the factory on your installations and applications.

As an exclusive distributor for Argentina and Uruguay, it we have a permanent stock of pumps and spare parts for fast delivery.

For more information contact us to drotec@drotec.com.ar or go to www.ansimag.com